Even two decades back, the lathe machine operators working round-the-clock used to toil a lot to rightly fix the job on machine beyond the sunny hours of the day. The common scene even in the ultra-modern workshops was – either a very tall and flexible or adjustable, multi-lever table lamp or a hanging luminaire with a high power GLS lamp focusing on the chucks and jaws. Well, it goes without saying that often the quality of the output used to suffer not because of the low precision of the machine but simply because of the improper lighting to watch the area of operation. Lights above the acid dilutor tanks used to burst being engulfed by moisture during addition of water for acid dilution. Also, filament- or discharge- based continuous or flash indicators used to draw a notable amount of current increasing the local temperature and overall electric charges.

Advent of LED has sorted out many such technical issues, which has added to the reliability of operations – and at the same time enhanced safety of the operators and other industrial equipment around. It is not only the case of ambient or task lighting in the industry. Today, LED-based luminaires are also being used on panels, especially they have carved a niche for visual signals – either as a part of a panel mount indicator or as a standalone strobe in a hazardous area or as an embedded part in the body of a machine. Thus, today LEDs are finding versatile use in industries.

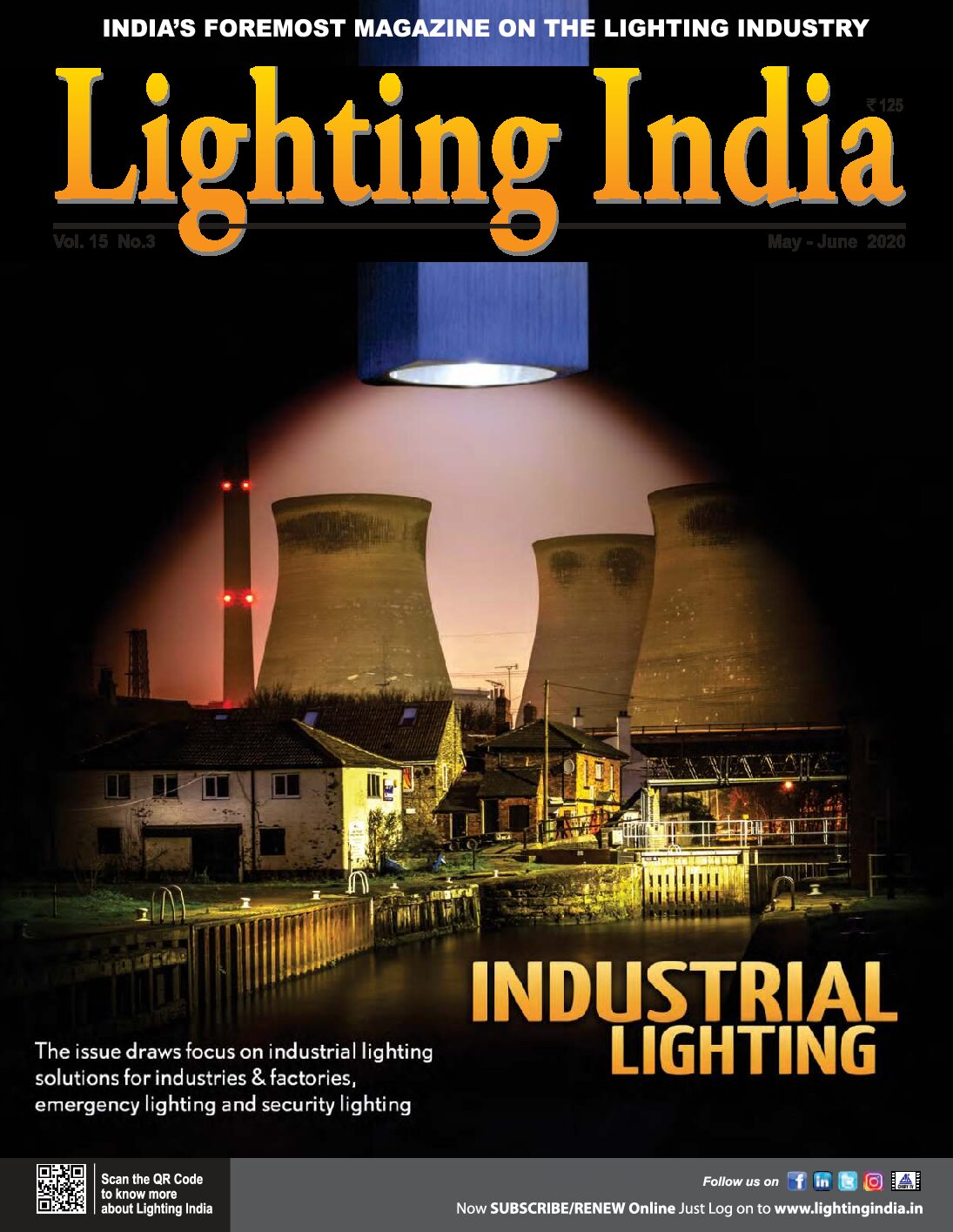

The current issue of Lighting India is dedicated to Industrial Lighting. As we all know that the expanse of the term ‘Industry’ is ever increasing, and in one issue everything cannot be covered, we have attempted to cover some of the sectors or segments where application of the LED-based emerging lighting systems is highly pronounced and promising.

So, wish you all a happy reading!

![]()

Publisher & Editor-In-Chief